in the present hyper-aggressive worldwide market place, manufacturers are frequently searching for website means to further improve performance, lessen expenses, and sustain the very best levels of excellent. standard ways of quality Command in many cases are time-consuming and susceptible to human error. This is when vision measurement machine suppliers are stepping in with innovative alternatives which are revolutionizing production processes. This article will delve into how Sophisticated eyesight measurement technological know-how, specially focusing on Easson's reducing-edge 3-axis CMM equipment, is not only Conference existing requires, but actively long run-proofing the entire manufacturing marketplace.

Table of contents:

AI Integration and Automation: the subsequent Frontier in Measurement

actual-Time facts Analysis: reducing Downtime, Maximizing Output

Easson’s 3-Axis CMM: Leading the demand in Scalability and Adaptability

AI Integration and Automation: the subsequent Frontier in Measurement

The combination of Artificial Intelligence (AI) and automation is no more a futuristic idea; it’s a existing-day fact significantly enhancing the abilities on the eyesight measurement equipment. AI algorithms empower these machines to master from broad datasets, autonomously optimize measurement parameters, and identify even by far the most refined defects with unparalleled pace and accuracy. This translates to a major reduction in human intervention, minimizing the potential risk of problems and accelerating inspection times. automatic dealing with systems even further streamline operations by seamlessly incorporating measurement processes into the prevailing manufacturing line, leading to a highly economical and optimized workflow. The enhanced throughput lets manufacturers to fulfill demanding manufacturing schedules with no compromising high-quality.

actual-Time knowledge Examination: reducing Downtime, Maximizing Output

serious-time facts Investigation is proving being a pivotal Software for producers striving to minimize costly creation downtime. modern day eyesight measurement devices are now Outfitted with strong application platforms effective at supplying fast and actionable feed-back on essential dimensions, tolerances, and system versions. This instantaneous info stream permits proactive identification of likely difficulties, like premature Device put on, machine calibration deviations, or substance inconsistencies, extensive prior to they escalate into significant defects or catastrophic manufacturing stoppages. By leveraging this genuine-time intelligence, brands can carry out instant corrective actions, improve course of action parameters, and finally make certain ongoing, uninterrupted output although minimizing squandered assets and scrap substance.

Easson’s 3-Axis CMM: top the demand in Scalability and Adaptability

Easson's three-axis CMM (Coordinate Measuring Machine) equipment are with the vanguard of eyesight measurement technological know-how, offering unparalleled scalability and adaptability to meet the evolving requires of recent production. These devices are meticulously engineered to accommodate a diverse array of portion sizes, complex geometries, and various content sorts, producing them Preferably suited to a large spectrum of manufacturing applications, from aerospace to automotive. As in depth on https://zh-easson.com/products/visual-video-cmm-measurement-machine-with-3-axis-001%CE%BCm-linear-encoder, Easson's machines are renowned for his or her exceptional precision, boasting remarkable 0.001μm linear encoders, guaranteeing the very best feasible degree of precision and repeatability. Their modular design and style facilitates seamless upgrades and customizations, letting brands to adapt quickly to shifting production demands and technological progress without having incurring considerable money expenditure. Furthermore, Easson's unwavering determination to consumer-pleasant software program interfaces and extensive education applications makes certain a seamless integration process and ideal utilization of their Superior technology, empowering operators To maximise the machine’s opportunity.

In conclusion, eyesight measurement technological innovation represents excess of just a classy top quality Manage Instrument; it is a strategic critical for makers seeking to long run-evidence their operations and manage a competitive edge in the present demanding industry. By embracing the power of AI integration, real-time info Evaluation, and highly scalable solutions like Easson's State-of-the-art three-axis CMM machines, manufacturers can attain unprecedented levels of precision, significantly decrease downtime, improve generation performance, and eventually drive substantial enhancements in profitability. The strategic financial commitment With this transformative technological innovation just isn't just an option but a necessity for extended-term results. Take the proactive stage to discover how Sophisticated eyesight measurement solutions can empower your company to thrive from the ever-evolving manufacturing landscape, and access out into a dependable vision measurement equipment provider to debate your precise wants and specifications these days.

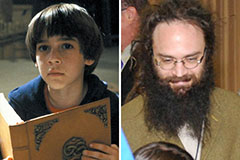

Barret Oliver Then & Now!

Barret Oliver Then & Now! Lark Voorhies Then & Now!

Lark Voorhies Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now! Rossy de Palma Then & Now!

Rossy de Palma Then & Now!